How do the excellent mechanical properties of machined copper parts help improve system reliability?

Release Time : 2025-06-16

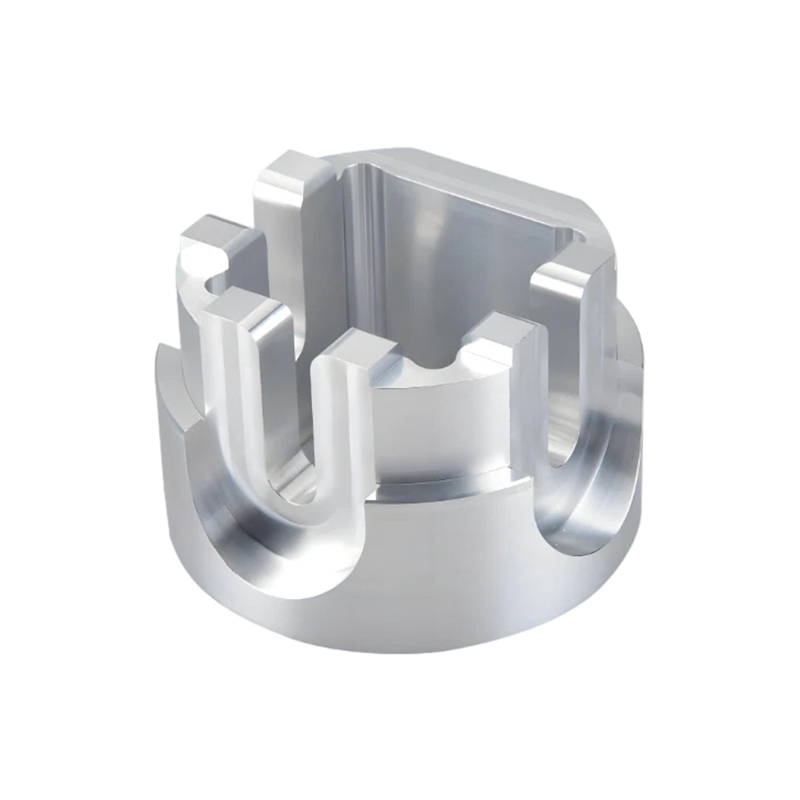

In modern industrial systems, the stability and durability of components directly determine the reliability of the overall equipment operation. As key structural and functional components, machined copper parts are widely used in electrical connections, radiators, plumbing pipes and other fields. Its excellent mechanical properties, electrical and thermal conductivity, and good corrosion resistance make it a core component for improving system efficiency and long-term stability.

1. High strength and good plasticity: ensure structural stability

After precision machining, high-quality electrolytic copper not only retains the good ductility and plasticity of the copper material itself, but also improves its strength and hardness through processing technology. This comprehensive performance enables copper parts to maintain a stable structural state when facing complex loads, vibrations or pressure changes, and is not prone to breakage or deformation.

For example, in electrical connectors, copper parts need to withstand the physical stress caused by frequent plugging and unplugging. High-quality copper parts can maintain good contact after thousands of operations due to their good fatigue resistance, thus avoiding resistance increase or signal interruption caused by looseness, significantly improving the stability and service life of the system.

2. High dimensional accuracy and good assembly consistency

Machine-processed copper parts are manufactured using advanced CNC equipment with extremely high dimensional accuracy and surface finish. This high-precision feature ensures that copper parts can achieve "seamless docking" during assembly and reduces stress concentration caused by excessive or too small matching clearance.

In automated production lines or precision instruments, copper parts are often used for positioning, guide rails or support structures. Its precise geometry and strict tolerance control help reduce friction loss during movement, improve the stability and response speed of the overall equipment operation, and reduce the possibility of failure from the source.

3. Excellent electrical and thermal conductivity to ensure efficient operation of the system

Copper is an excellent conductive material second only to silver, and also has excellent thermal conductivity. In applications such as electrical connections, busbar arrangement, and power module heat dissipation, copper parts can quickly conduct current and heat, effectively preventing thermal failure or aging problems caused by local overtemperature.

Taking power equipment as an example, copper busbars are the core components of energy transmission in the power distribution system. Its efficient conductivity can significantly reduce line losses and heat generation, thereby extending equipment life and improving energy utilization. In electronic radiators, copper parts can quickly conduct the heat generated by the chip to ensure that electronic components work within a safe temperature range and avoid performance degradation or even damage due to overheating.

4. Strong corrosion resistance and adaptability to a variety of complex environments

Copper has natural antioxidant and corrosion resistance properties, especially suitable for environments with humidity, high temperature or chemical media. Machined copper parts are usually subjected to surface treatments such as passivation and plating to further enhance their stability under harsh conditions.

For example, in plumbing systems, copper pipe joints and valves are exposed to water flow and temperature changes for a long time. If ordinary metals are used, rust and scaling may occur. Copper parts, with their excellent corrosion resistance, can maintain sealing and structural integrity for a long time, greatly reducing the frequency of water leakage and maintenance, and providing a strong guarantee for the reliable operation of the building water supply system.

5. Multi-scenario adaptation to improve system compatibility and scalability

Copper parts can not only be used as functional components alone, but also can be used in combination with other metals (such as aluminum, stainless steel) or non-metallic materials. Its good weldability, machinability and connection performance make it highly adaptable in different systems.

For example, in the battery management system of new energy vehicles, copper busbars are used to connect multiple battery cells. Its excellent conductivity and structural rigidity can not only ensure the stable transmission of large currents, but also adapt to the vibration and temperature changes during vehicle driving, and improve the safety and reliability of the entire battery system.

In summary, machined copper parts play an irreplaceable role in various industrial systems with their excellent mechanical properties, high-precision processing quality, excellent electrical and thermal conductivity, and good corrosion resistance. They not only ensure the stable operation of the equipment, but also quietly improve the efficiency and reliability of the overall system in details.

1. High strength and good plasticity: ensure structural stability

After precision machining, high-quality electrolytic copper not only retains the good ductility and plasticity of the copper material itself, but also improves its strength and hardness through processing technology. This comprehensive performance enables copper parts to maintain a stable structural state when facing complex loads, vibrations or pressure changes, and is not prone to breakage or deformation.

For example, in electrical connectors, copper parts need to withstand the physical stress caused by frequent plugging and unplugging. High-quality copper parts can maintain good contact after thousands of operations due to their good fatigue resistance, thus avoiding resistance increase or signal interruption caused by looseness, significantly improving the stability and service life of the system.

2. High dimensional accuracy and good assembly consistency

Machine-processed copper parts are manufactured using advanced CNC equipment with extremely high dimensional accuracy and surface finish. This high-precision feature ensures that copper parts can achieve "seamless docking" during assembly and reduces stress concentration caused by excessive or too small matching clearance.

In automated production lines or precision instruments, copper parts are often used for positioning, guide rails or support structures. Its precise geometry and strict tolerance control help reduce friction loss during movement, improve the stability and response speed of the overall equipment operation, and reduce the possibility of failure from the source.

3. Excellent electrical and thermal conductivity to ensure efficient operation of the system

Copper is an excellent conductive material second only to silver, and also has excellent thermal conductivity. In applications such as electrical connections, busbar arrangement, and power module heat dissipation, copper parts can quickly conduct current and heat, effectively preventing thermal failure or aging problems caused by local overtemperature.

Taking power equipment as an example, copper busbars are the core components of energy transmission in the power distribution system. Its efficient conductivity can significantly reduce line losses and heat generation, thereby extending equipment life and improving energy utilization. In electronic radiators, copper parts can quickly conduct the heat generated by the chip to ensure that electronic components work within a safe temperature range and avoid performance degradation or even damage due to overheating.

4. Strong corrosion resistance and adaptability to a variety of complex environments

Copper has natural antioxidant and corrosion resistance properties, especially suitable for environments with humidity, high temperature or chemical media. Machined copper parts are usually subjected to surface treatments such as passivation and plating to further enhance their stability under harsh conditions.

For example, in plumbing systems, copper pipe joints and valves are exposed to water flow and temperature changes for a long time. If ordinary metals are used, rust and scaling may occur. Copper parts, with their excellent corrosion resistance, can maintain sealing and structural integrity for a long time, greatly reducing the frequency of water leakage and maintenance, and providing a strong guarantee for the reliable operation of the building water supply system.

5. Multi-scenario adaptation to improve system compatibility and scalability

Copper parts can not only be used as functional components alone, but also can be used in combination with other metals (such as aluminum, stainless steel) or non-metallic materials. Its good weldability, machinability and connection performance make it highly adaptable in different systems.

For example, in the battery management system of new energy vehicles, copper busbars are used to connect multiple battery cells. Its excellent conductivity and structural rigidity can not only ensure the stable transmission of large currents, but also adapt to the vibration and temperature changes during vehicle driving, and improve the safety and reliability of the entire battery system.

In summary, machined copper parts play an irreplaceable role in various industrial systems with their excellent mechanical properties, high-precision processing quality, excellent electrical and thermal conductivity, and good corrosion resistance. They not only ensure the stable operation of the equipment, but also quietly improve the efficiency and reliability of the overall system in details.