Why have aluminum parts become an indispensable key material in the field of high-end manufacturing?

Release Time : 2025-06-04

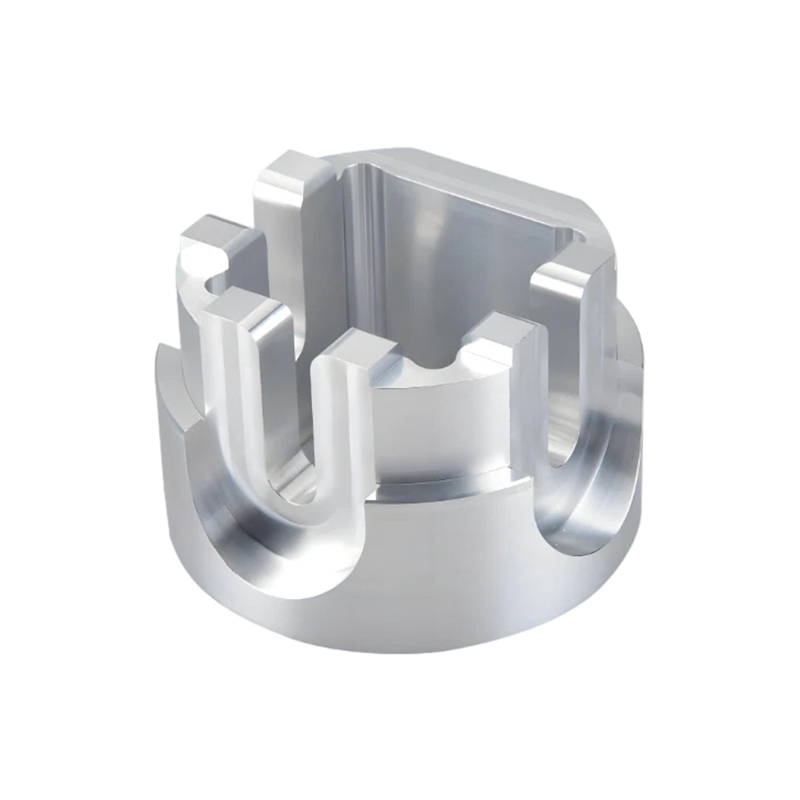

In modern industrial manufacturing, the choice of materials is directly related to the performance, life and market competitiveness of products. Aluminum parts are widely used in aerospace, automobile manufacturing, electronic equipment, mechanical equipment and other high-tech and civilian fields due to their multiple advantages such as light weight, high strength, good thermal conductivity, strong corrosion resistance, high processing precision and exquisite appearance. So, what are the outstanding features of this product that combines functionality and aesthetics, making it a "darling" in many industries?

First of all, the biggest advantage of aluminum parts lies in its excellent lightweight characteristics. Aluminum parts made of high-strength aluminum alloy materials greatly reduce the overall weight while ensuring structural strength. This feature is particularly important for industries such as aerospace and automobile manufacturing. It can not only improve fuel efficiency or flight endurance, but also effectively reduce carbon emissions, which is in line with the current development trend of green manufacturing.

Secondly, aluminum parts have excellent thermal conductivity. This feature makes it perform well in the heat dissipation system of electronic equipment, such as LED lamp housing, computer CPU heat sink, new energy vehicle battery module bracket and other fields. Aluminum parts can be seen. Good heat conduction not only helps to improve the stability of equipment operation, but also prolongs the service life of electronic components and ensures long-term and efficient operation of products.

Furthermore, aluminum parts have excellent corrosion resistance and oxidation resistance. The chemical properties of aluminum alloy materials themselves are stable, and the surface can be further enhanced through processes such as anodizing, spraying, and electroplating. It can maintain a good state even in humid, salt spray or acid-base environments, and is suitable for outdoor equipment, marine engineering, chemical machinery and other complex working conditions.

In addition, aluminum parts have high processing accuracy and strong adaptability. The development of modern CNC machining technology enables aluminum parts to achieve micron-level precision molding to meet the requirements of complex structures and high matching. Whether it is precision parts, housing components, or structural support parts, aluminum parts can provide stable and reliable performance. At the same time, its good plasticity also facilitates various processing methods such as stamping, casting, turning, milling, etc., providing more possibilities for product design.

It is worth mentioning that the appearance processing effect of aluminum parts is also excellent. After polishing, brushing, sandblasting, anodizing and other processes, the surface of aluminum parts can present a variety of visual effects such as metallic luster, matte texture, color coating, etc., which is both beautiful and technological, and is particularly suitable for consumer electronics, smart home devices, high-end home appliances and other products with high requirements for appearance.

From the application point of view, aluminum parts have become one of the key components in many industries. In the aerospace field, it is widely used in aircraft skeletons and engine parts; in automobile manufacturing, it is used for body structural parts, wheels, cooling systems; in electronic equipment, it is used as housings, brackets, radiators, etc. It can be said that wherever lightweight, high-performance and high-reliability materials are needed, there are aluminum parts.

In summary, aluminum parts have become an indispensable and important material in modern high-end manufacturing industry with its multiple advantages such as light weight, high strength, good thermal conductivity, strong corrosion resistance, high processing precision and exquisite appearance. Whether in improving product performance, reducing energy consumption, or in expanding product functions and beautifying appearance, it has shown great value. With the continuous development of new material technology and intelligent manufacturing, the application prospects of aluminum parts will be broader, and will continue to promote technological progress and industrial upgrading in all walks of life.

First of all, the biggest advantage of aluminum parts lies in its excellent lightweight characteristics. Aluminum parts made of high-strength aluminum alloy materials greatly reduce the overall weight while ensuring structural strength. This feature is particularly important for industries such as aerospace and automobile manufacturing. It can not only improve fuel efficiency or flight endurance, but also effectively reduce carbon emissions, which is in line with the current development trend of green manufacturing.

Secondly, aluminum parts have excellent thermal conductivity. This feature makes it perform well in the heat dissipation system of electronic equipment, such as LED lamp housing, computer CPU heat sink, new energy vehicle battery module bracket and other fields. Aluminum parts can be seen. Good heat conduction not only helps to improve the stability of equipment operation, but also prolongs the service life of electronic components and ensures long-term and efficient operation of products.

Furthermore, aluminum parts have excellent corrosion resistance and oxidation resistance. The chemical properties of aluminum alloy materials themselves are stable, and the surface can be further enhanced through processes such as anodizing, spraying, and electroplating. It can maintain a good state even in humid, salt spray or acid-base environments, and is suitable for outdoor equipment, marine engineering, chemical machinery and other complex working conditions.

In addition, aluminum parts have high processing accuracy and strong adaptability. The development of modern CNC machining technology enables aluminum parts to achieve micron-level precision molding to meet the requirements of complex structures and high matching. Whether it is precision parts, housing components, or structural support parts, aluminum parts can provide stable and reliable performance. At the same time, its good plasticity also facilitates various processing methods such as stamping, casting, turning, milling, etc., providing more possibilities for product design.

It is worth mentioning that the appearance processing effect of aluminum parts is also excellent. After polishing, brushing, sandblasting, anodizing and other processes, the surface of aluminum parts can present a variety of visual effects such as metallic luster, matte texture, color coating, etc., which is both beautiful and technological, and is particularly suitable for consumer electronics, smart home devices, high-end home appliances and other products with high requirements for appearance.

From the application point of view, aluminum parts have become one of the key components in many industries. In the aerospace field, it is widely used in aircraft skeletons and engine parts; in automobile manufacturing, it is used for body structural parts, wheels, cooling systems; in electronic equipment, it is used as housings, brackets, radiators, etc. It can be said that wherever lightweight, high-performance and high-reliability materials are needed, there are aluminum parts.

In summary, aluminum parts have become an indispensable and important material in modern high-end manufacturing industry with its multiple advantages such as light weight, high strength, good thermal conductivity, strong corrosion resistance, high processing precision and exquisite appearance. Whether in improving product performance, reducing energy consumption, or in expanding product functions and beautifying appearance, it has shown great value. With the continuous development of new material technology and intelligent manufacturing, the application prospects of aluminum parts will be broader, and will continue to promote technological progress and industrial upgrading in all walks of life.